QUALITY CONTROL

QUALITY CONTROL

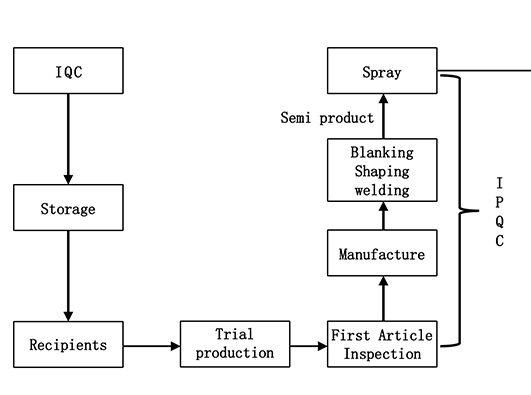

1. Incoming inspection, process inspection

Incoming inspection: According to the drawings and operation instructions, we implement strict control throughout raw, packaging, plastic, and powder materials. We are also equipped with three-dimensional CMM, hardness tester, spectrometer, temperature and humidity tester, torque wrench, cardboard bursting tester to meet all size, appearance, material, sustainability, and other testing requirements.

Process inspection: Conduct inspections every 2 hours according to drawings/SIP/SOP, measure and test the size, function, safety, and appearance to ensure that the product is accurate and meets the design and customer requirements.

IQC

IQC

Storage

Storage

Recipients

Recipients

Trial production

Trial production

IPQC

First Article Inspection->Manufacture->Blanking、Shaping、Welding->Spray

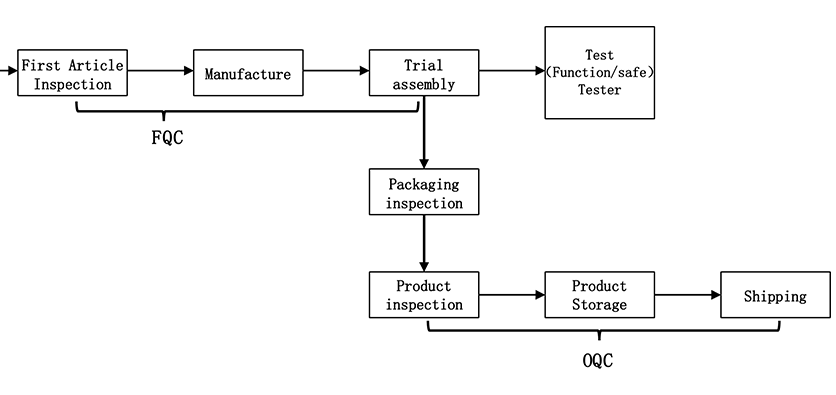

2. Final inspection, testing, and shipment inspection

Final Inspection: Conduct inspections every 2 hours to inspect the operations, equipment, personnel, and parts according to the drawings/SIP/SOP, ensuring that the operation process meets the specified standards of the design and customer requirements.

Testing: With our in-house UL accredited laboratory, testing personnel and equipment undergoing professional training and third-party calibration, our testing procedures and report are further rigorous and solid.

Pre-Shipment Inspection: With comprehensive QC skills and additional training from a third-party inspection company, we have a clear understanding of product appearance, function, and safety standards, and are proficient in using AQL methods to ensure effective inspection results.

FQC

First Article Inspection->Manufacture->Trial assembly

Packaging inspection

Packaging inspection

OQC

Product inspection->Product Storage->Shipping

一.新产品开发质量控制

在产品开发之初,通过合理的设计和客户的需求,确保产品的实用性和可靠性。在大规模生产之前的设计阶段测试每个样品并检测每个缺陷。

项目立项

我们不仅选择分销商而且还选择来料

项目立项

我们不仅选择分销商而且还选择来料

项目立项

我们不仅选择分销商而且还选择来料

项目立项

我们不仅选择分销商而且还选择来料

项目立项

我们不仅选择分销商而且还选择来料